Injection Molding

What is Injection Molding?

Injection molding is a manufacturing process used to produce parts by injecting molten material into a mold. The process begins with heating the chosen material—typically plastic—until it becomes liquid. This molten material is then forced into a custom-made mold cavity under high pressure. Once the material cools and solidifies, it takes the shape of the mold, forming the final part.

Injection molding is known for its ability to produce high-precision parts at high volumes, making it a popular choice in industries such as automotive, electronics, medical devices, and consumer goods. The process is highly efficient and allows for complex shapes and intricate details to be replicated consistently, with minimal waste.

Injection Molding at VEKO Technology

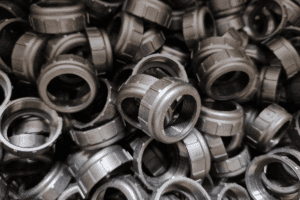

At VEKO Technology, our injection molding capabilities are employed across a diverse range of applications, from precision-engineered plastic components and automotive parts to complex connector housings for the electronics industry.

We serve industries such as automotive, design, electronics, railway, and beyond. Our expertise and commitment to quality ensure that every molded part we produce meets the demands of these sectors.

VEKO Technology can offer a wide variety of injection molding services including overmolding. From mold design to high volume production, we provide tailored solutions that ensure high-quality components perfectly suited to your specific requirements. Whether it’s for prototyping or high-volume production, our injection molding services deliver precision, reliability, and excellence every time.