Prototypes

Prototype Manufacturing

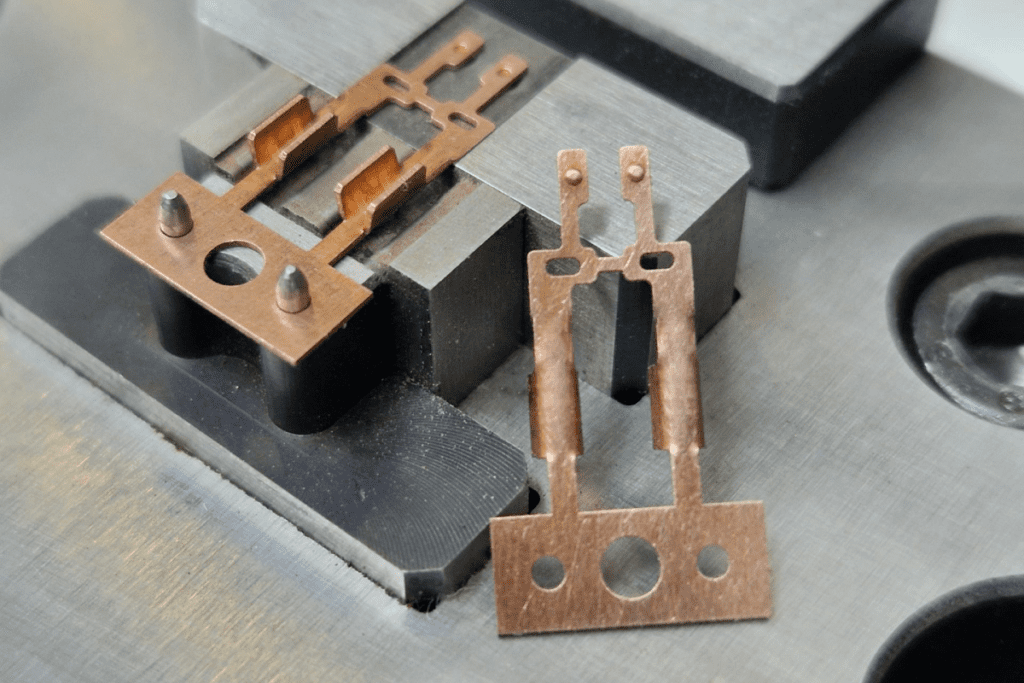

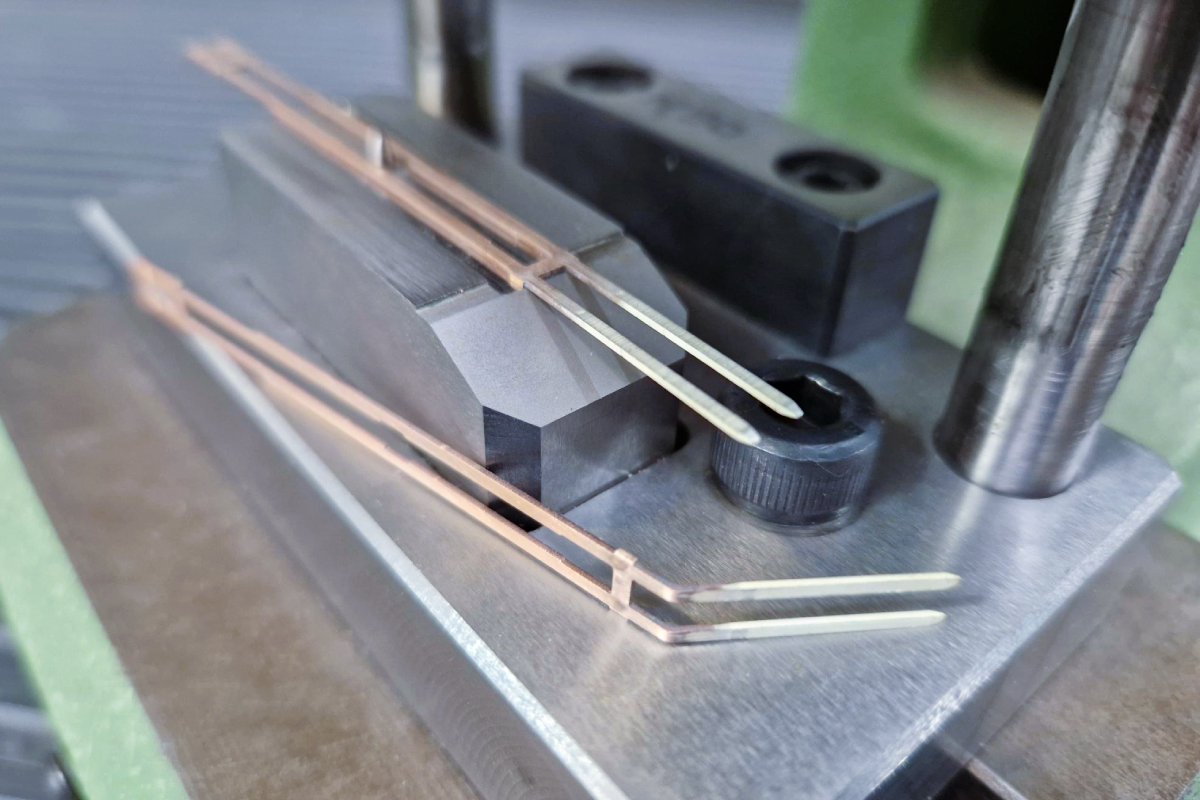

Understanding the critical role prototypes play in product development, especially for leadframes and connectors, VEKO Technology offers comprehensive prototype manufacturing services. We utilize wire eroding or laser cutting techniques, using the same base material as the final product to ensure accuracy and consistency. Additionally, we build manual tools for bending and embossments operations, allowing for precise customization of your prototypes.

To further streamline the process, we collaborate with an external selective plating supplier known for high quality and short lead times, ensuring that the prototypes are fully functional and resemble the final production parts. Our approach allows you to optimize your leadframes and connectors before full-scale production, saving time and reducing costs.

Our rapid prototyping service, including plating, allows you to test and refine designs, ensuring everything meets your specifications before moving to production.

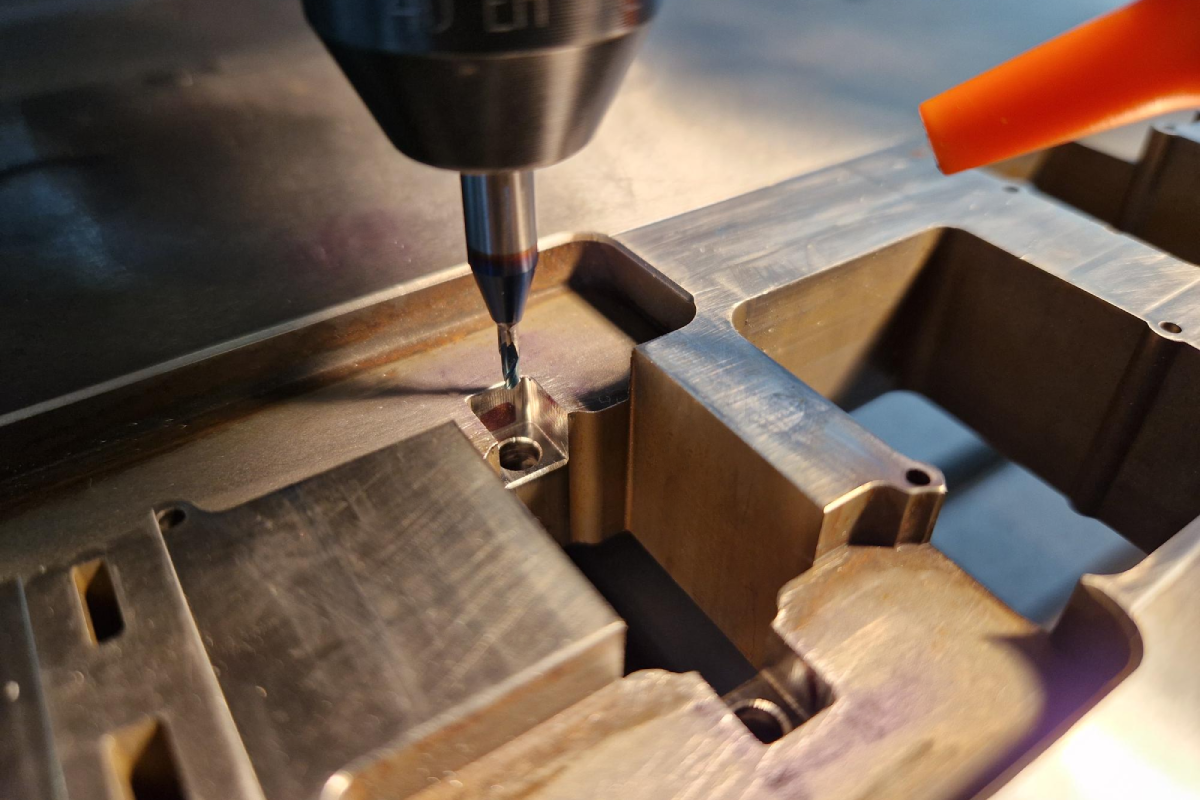

After finalizing the prototype, we can manufacture the tools and dies needed for production. Our in-house capabilities ensure high-quality tools tailored to your project, setting the stage for efficient production.

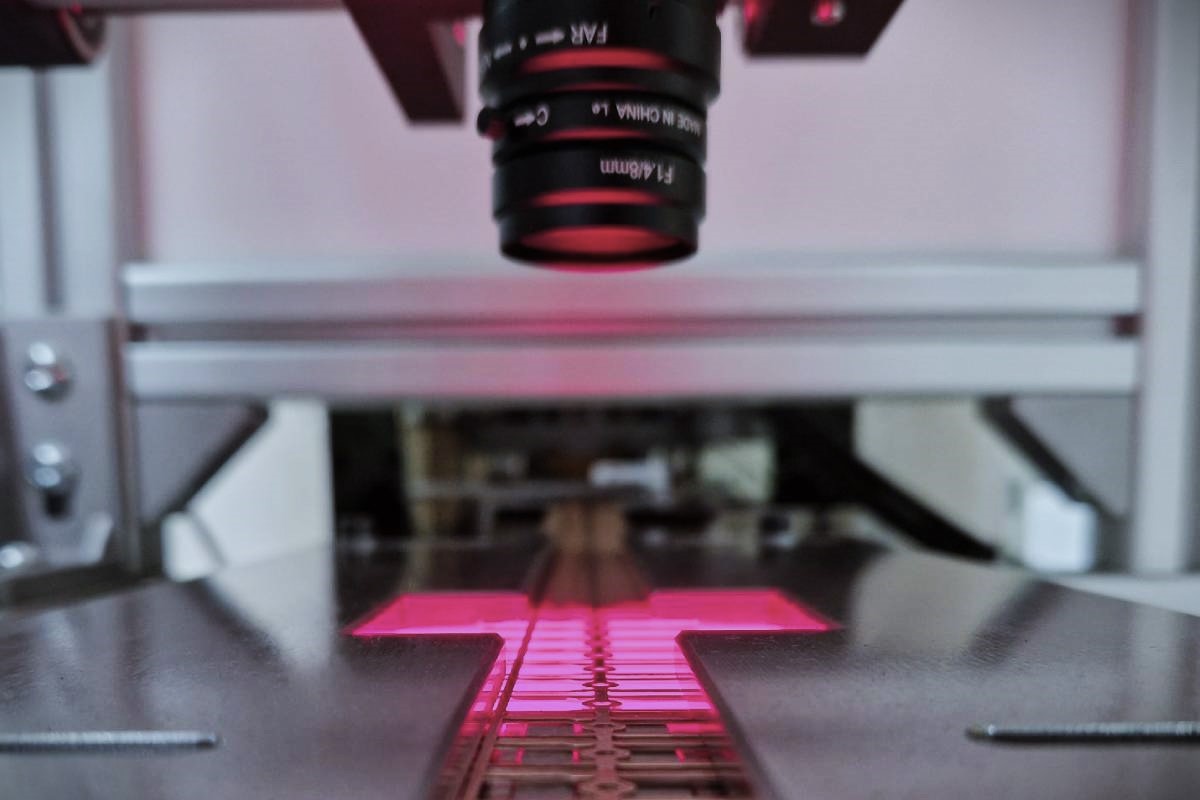

With tools and dies in place, we seamlessly transition to full-scale production. VEKO Technology manages the entire process, delivering consistent, high-quality products from start to finish.