Metal Stamping

What is Metal Stamping?

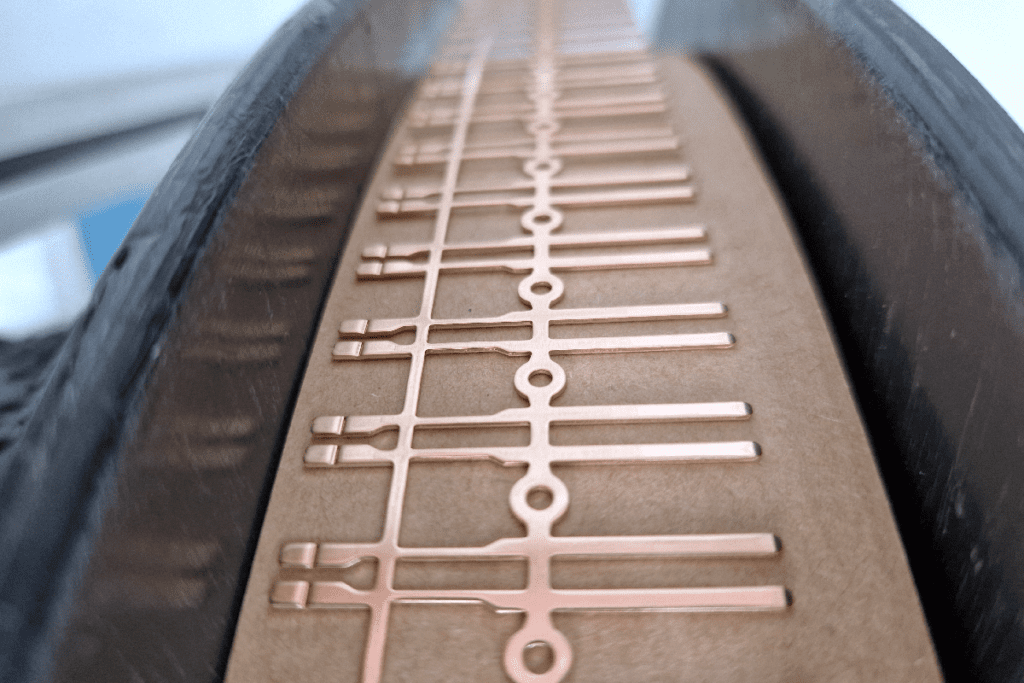

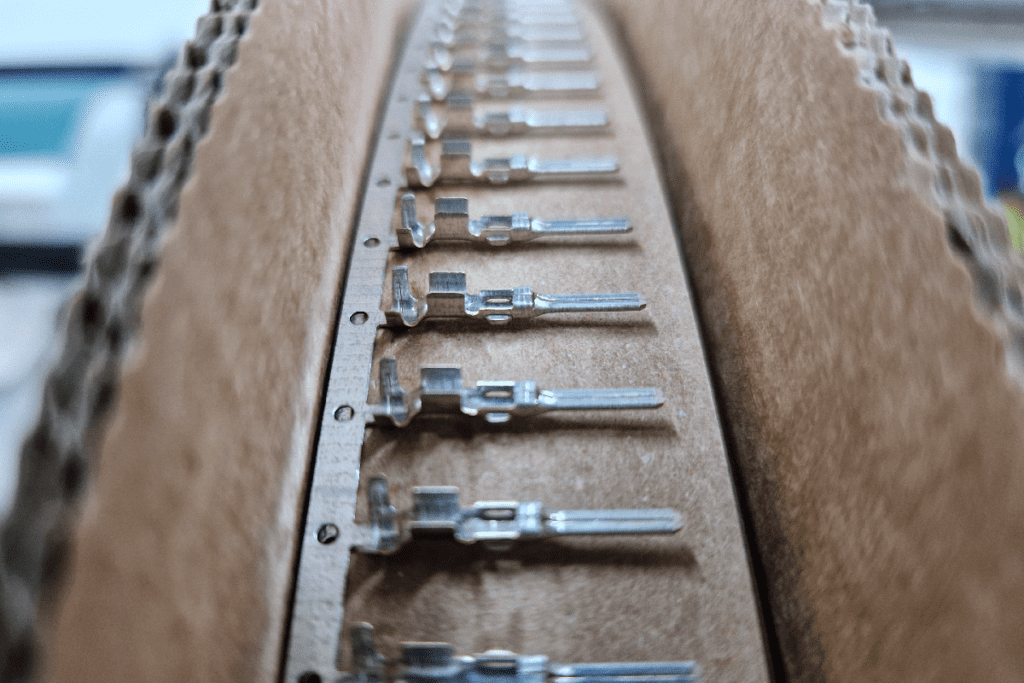

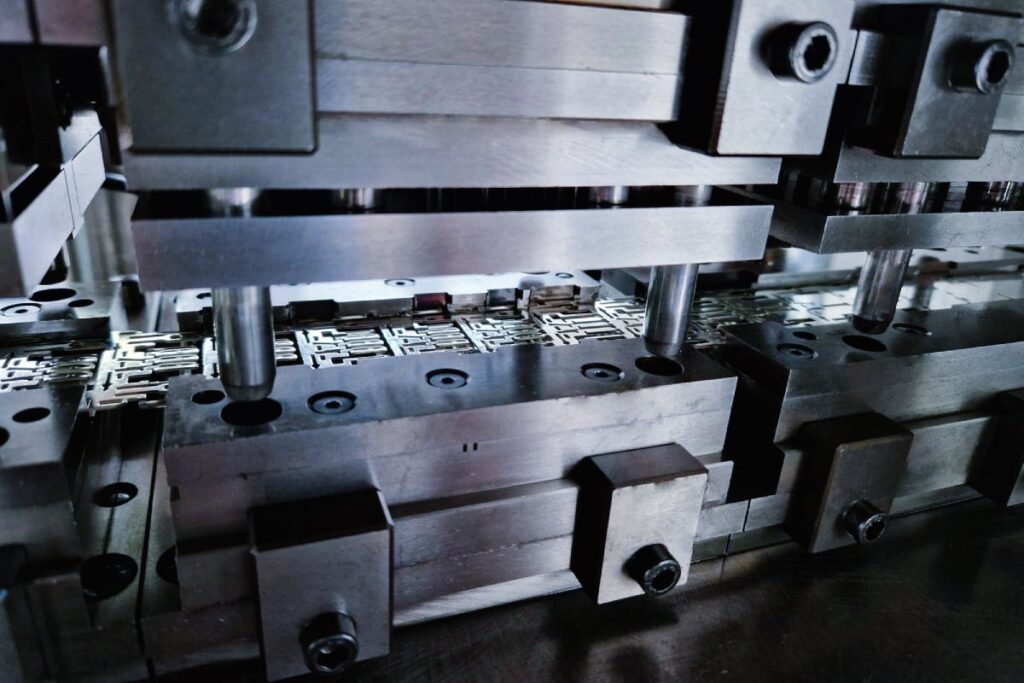

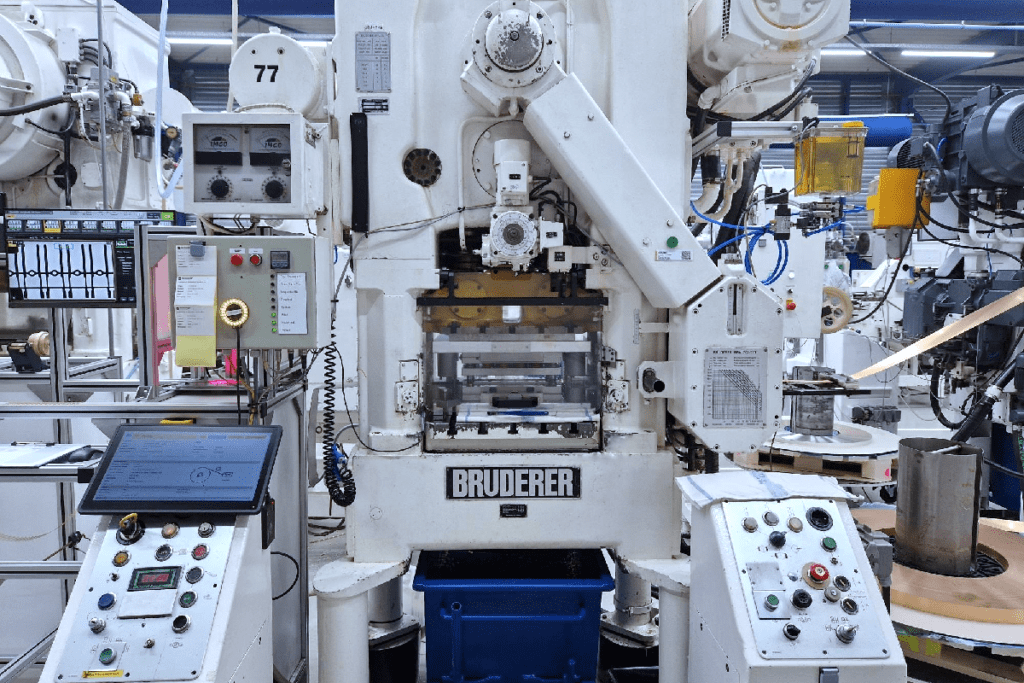

Progressive Metal Stamping or Die Stamping is a high-speed, advanced manufacturing process that utilizes a sequence of stations within a die to shape and cut metal strips into components. Each station in the die performs a specific operation, such as punching, bending, or coining, progressively transforming the metal strip as it moves through the die. This method ensures exceptional precision and consistency, making it ideal for producing complex parts at both low and high volumes.

The ability to perform multiple operations in a single pass not only increases efficiency but also reduces production costs, making progressive metal stamping a highly efficient and cost-effective solution for a wide range of industries.

Our high quality stamping equipment with inline measurement systems and skilled technicians will guarantee high quality and cost-efficiency, meeting customer specific requirements standards of various industries.

Metal Stamping at VEKO Technology

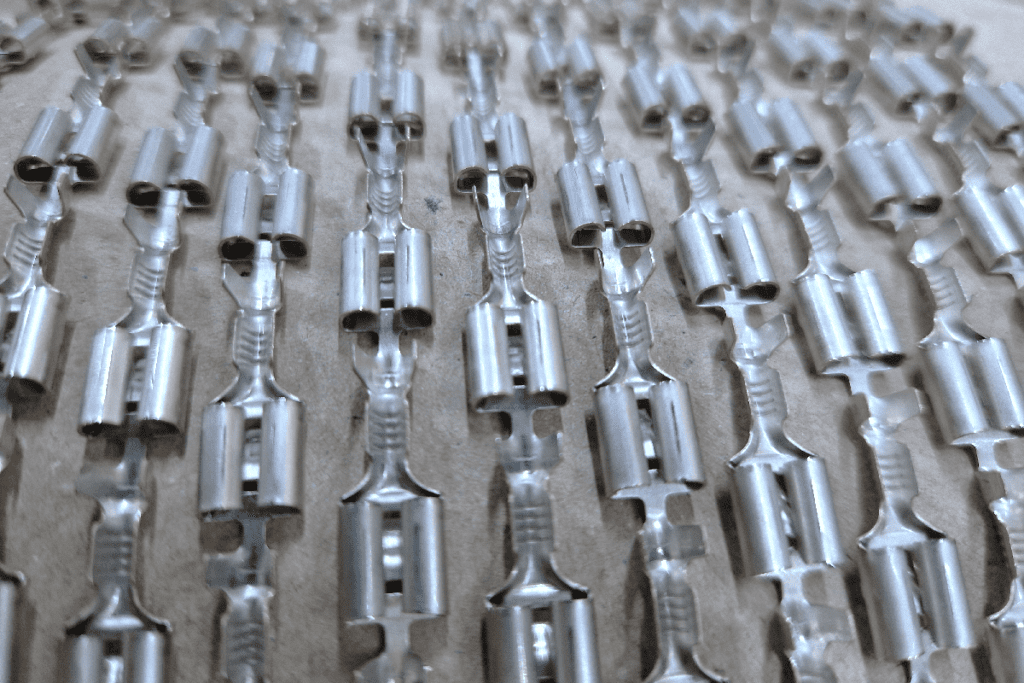

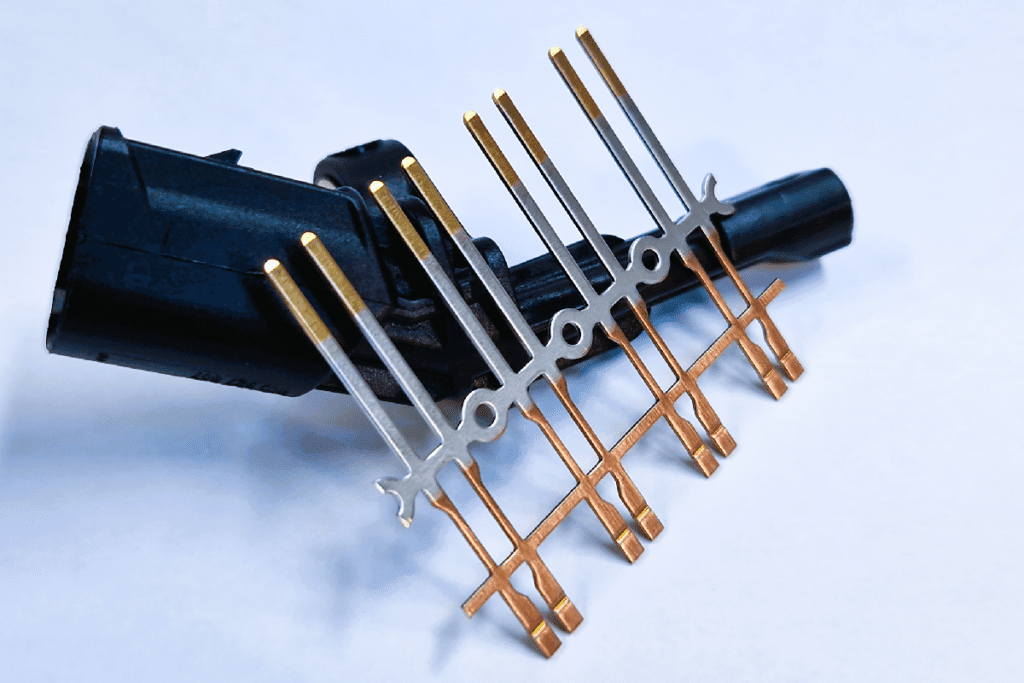

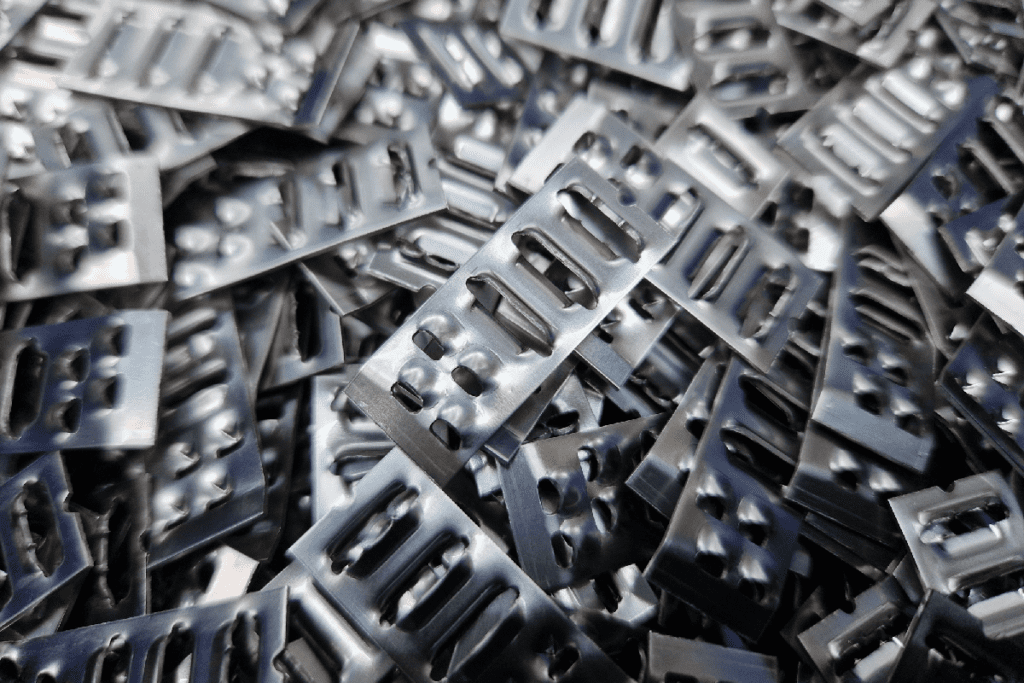

Our progressive metal stamping capabilities are utilized across a wide range of applications, from intricate PCB connectors and automotive parts to lighting contacts and stainless steel grippers.

Industries we serve include automotive, electronics, data communication, medical, solar and more. Our expertise and high quality level ensures that each stamped part meets the requirements of these sectors. For over 20 years, VEKO Technology is part of the supplychain in the automotive industry for original equipment manufacturers.

VEKO Technology collaborates with carefully selected suppliers to provide comprehensive plating solutions for both loose piece and reel-to-reel plating applications. We can offer a total solution for stamped parts with a variety of plating options, including gold, silver, tin, nickel, and more. This ensures a high-quality, precisely plated components tailored to your specific needs.

The benefits of VEKO Technology Metal Stamping

As Metal Stamping Company, VEKO Technology can offer tailored solutions to you, including:

- High Quality level: VEKO Technology ensures as IATF 16949 and ISO 14001 precision and consistency in every product, meeting the industry standards.

- Cost-effectiveness: Our efficient production techniques and advanced tooling reduce material waste and production costs, providing you with high-quality parts at competitive prices.

- Flexibility: With our versatile manufacturing capabilities, VEKO Technology can easily adapt to custom specifications and varying production volumes, offering tailored solutions that meet your specific needs.

- Total solution: Veko Technology can offer the complete solution from Prototypes, tooling and production of metal stamped parts. Beside metal stamping VEKO Technology can also offer a combination of in house activities as Injection Moulding and Assembly or outsource activities as Reel to Reel Plating.

Our capabilities and expertise

We specialize in working with a variety of materials, including but not limited to:

- Copper Alloys (Bronze): CuSn6, CuSn4, CuSn0.15 (available in both blank and tinned finishes)

- Copper Alloys (Brass): CuZn30, CuZn37 (available in both blank and tinned finishes)

- Stainless Steel: AISI 301, CrNi177

- Specialty Alloys: CuBe2, CuCr1Zr, CuNi9Sn2, CuNi18Zn20

To enhance our offerings, we provide plating services in partnership with our trusted suppliers. Available plating options include selective and barrel plating of:

- Gold (Au)

- Silver (Ag)

- Tin (Sn)

- Nickel (Ni)

- Copper (Cu)

- Palladium (Pd)

At VEKO Technology, we are committed to delivering excellence in every aspect of our production process, ensuring components of the highest quality.

Portfolio